Innovative

Solutions

for Optical

Inspection

Solutions

More details visible by tapping on pictures.

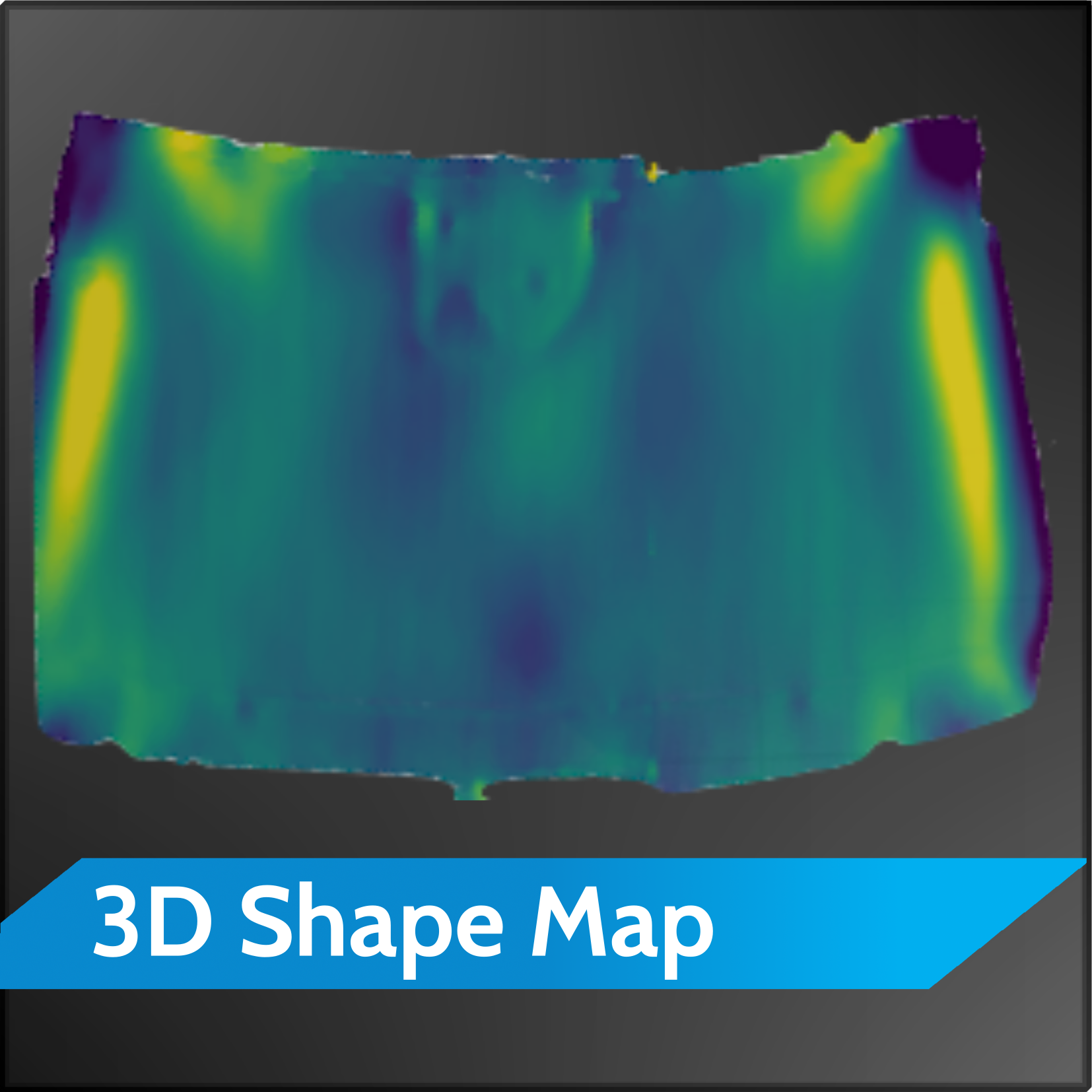

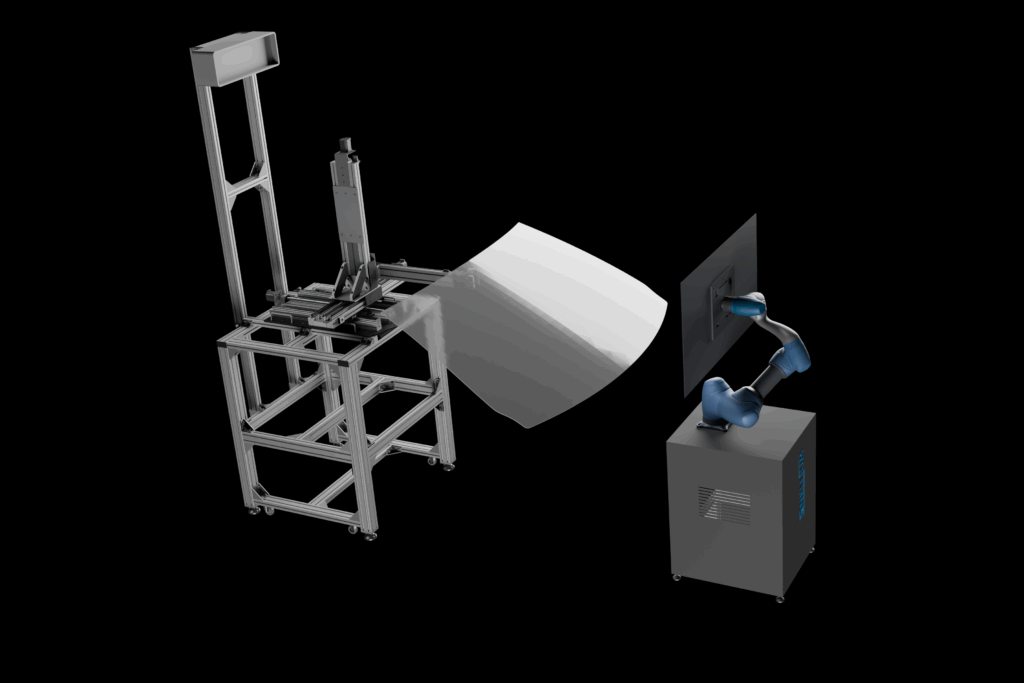

Optical System for Specular Surfaces

Single-shot deflectometry system for mapping the inner and outer shapes and curvatures of transparent objects, regardless of their size or shape.

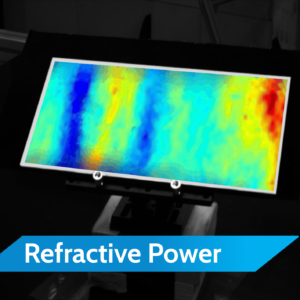

Refractive Power in Deflection Mode

The optical power of transparent and reflective objects is derived from their inner and outer topography.

Prediction of HUD Performances

The topography of the windshield provides the image quality for the heads-up display and can be used to evaluate compliance.

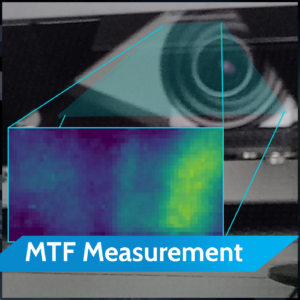

Modulation Transfer Function

Prediction of MTF of camera systems mounted behind protective screens in operative conditions, as used in Advanced Driver Assistance Systems (ADAS).

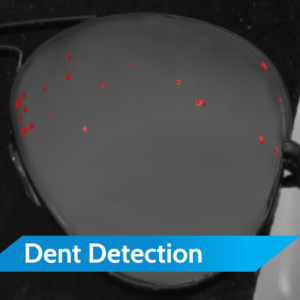

Cosmetic Inspection

Single-shot camera based algorithm in deflection mode for detecting contaminations and damages on the surface and in the bulk of transparent objects.

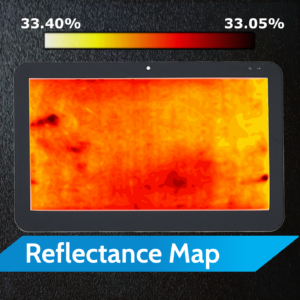

Coating Uniformity Check

Transmittance and reflectance maps of reflective and transparent objects are obtained using a single-shot camera-based setup.

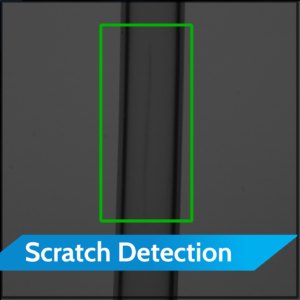

Internal Scratch Detection

Fast detection of internal scratches in transparent tubes.

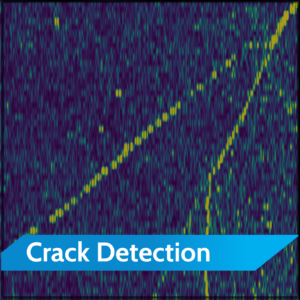

Detection of Cracks in Materials

Advanced profilometry algorithm for detecting hidden cracks induced by mechanical shocks through the analysis of surface roughness variations.

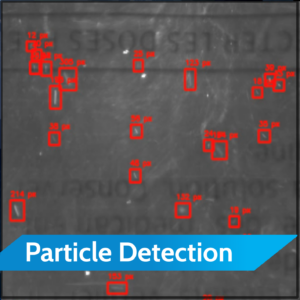

Solid Contaminant Detection

Live detection of particle contamination in liquids.

Surface Roughness Characterisation

Single-shot camera-based algorithm for detecting paint quality and surface roughness of reflective and semi-reflective materials.

On-Demand Optical and Software Setup

Design, prototyping, integration, and testing of optical setups for custom applications.

Mathematical Model for Synthetic Data

Experts in machine learning training for optical inspection applications.

Your Vision

Our Solution

Your Success!

Markets

More details visible by tapping on pictures.

Automotive Glazings

Quality lab and production non-destructive inspection of all types of glazing, including windshields, sidelights, backlights, and sunroofs, for the automotive and transportation industries.

Aeronautical Parts

Geometry check and distortion analysis of curved transparencies for aeronautical applications.

Architectural Glass

Optical inspection of the edges and geometry of curved glass, as well as a flatness check of tempered glass.

Car Damage Inspection

Inspection of paint and damage on cars for the rental market, as well as evaluations for second-hand sales and end-of-line applications.

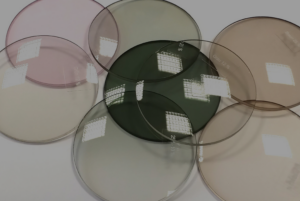

Transparencies

Cosmetic inspection of eyewear, lenses, displays, and covers crafted from plastic, glass, and sapphire.

Mirrors

Flatness inspection and optical characterization of mirrors.

Autonomous Systems

Improving AI performance for autonomous driving systems by considering the impact of real camera protective screens during the training process.

Healthcare Supplies

Inspection of the flatness of Petri dishes, quality assessment of tubes, and detection of plastic contamination in transparent liquids.

Security

Inspection of bulletproof glass and identification of cracks in ceramics and metals for defense applications.

Where R&D Meets

Quality Inspection Excellence

Products

More details visible by tapping on pictures.

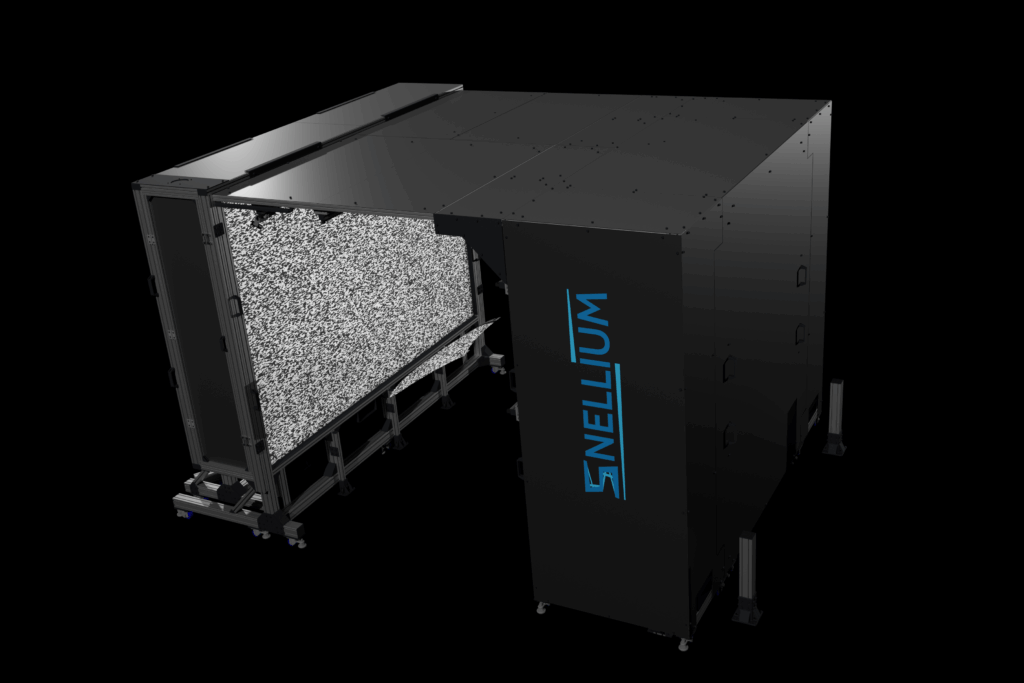

mg-PROMETE

The Ultimate All-in-One Device for Non-Destructive Quality Inspection of Glazings and Transparent Materials

ADAS-Inspector

The Sole Device Capable of Predicting ADAS Camera MTF Under Any Operational Conditions

SNELLIUM

Your R&D Partner in Inspection

About

Mission

SNELLIUM's origins trace back to the RePRO glass project, a spin-off initiative from Université libre de Bruxelles (ULB) that began in 2018 for adapting optical diagnostics developed for space applications to ground industrial quality control of automotive glazing. Established in December 2021, the company is committed to innovating the design of laboratory and production line equipment, incorporating advanced solutions for optical quality inspection and analysis.

The company's primary objective is to improve optical quality inspection systems by leveraging advanced software-based technologies to reduce hardware complexity, lower overall costs, and simplify integration into both new and existing processes. This approach combines multiple optical inspections into a single device, enabling cost-effective, non-destructive quality inspection for industries of all sizes.

By staying at the forefront of optical inspection technology and partnering with industry leaders as a technology provider, we gain a competitive edge and continuously improve product quality monitoring and analysis through our patented dynamic solutions.

Team

Tzevelecos Wassilis

CEO

van Pelt Vincent

CTO

Abbas Lakkis

CPO

Franchomme Florence

IT Engineer

Óscar Mate Castro

IT Engineer

Medina Alberto

IT Scientist

Casier Jonathan

IT Developer

Our Partners

Contact

Complete and send us the following form. We will answer you in 48 hours.

Copyright © 2025 Snellium All Rights Reserved